Download the PDF here Trident install

Trident/Rocket 3 Throttle gantry conversion.

JRC 14-315A

Thank you for your purchase of

JRC Engineering carburettor conversion for the BSA and

Triumph 3 cylinder motorcycles 1968-1974 A75

and T150. Please note the T160 uses a different

adaptor set. These instructions should make the

job of changing carburettors easy. If you do not

feel qualified to do this job please contact us and

we can refer you to a qualified professional in

your area. Figure 1 shows the completed assembly.

Step 1. Disconnect the battery to remove any

chance of a spark igniting fuel.

Step 2. Remove the stock fuel lines from the fuel taps, remove the fuel tank mounting bolts at the front and rear of the tank. Be careful not to inadvertently

turn the fuel tap on while removing the fuel tank. Set the tank in a safe place away from

the work area. Please note that gasoline vapour can travel a long way and can

be ignited by a dryer pilot light and flash back a long distance. Always work in a

well ventilated area and be very careful with gasoline.

Step 3. Slack the hose clamps that secure the gantry to the cylinder head. Remove

the throttle cable from the gantry. Remove the stock air box by slacking

the two securing bolts. Lift the carburettor up gently until the gantry comes

away from the rubber inlet manifolds.

Figure 1

Step 4. Take the carburettor set outside and turn upside down to drain the

remaining fuel from the float chambers. Do this in a well ventilated area.

Step 5. Remove the six screws securing the carburettor tops to the bodies.

Loosen the throttle rod lock nuts and unscrew the throttle rods from the gantry

pivot. Remove the fuel line assembly from the old carburettors. Remove the 6

half inch nuts that secure the carburettors to the gantry and separate the carburettors

from the gantry.

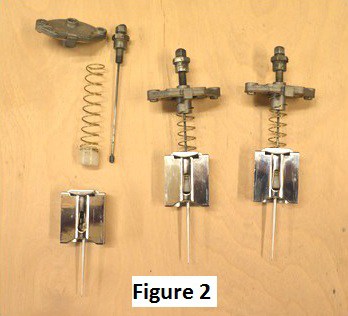

Step 6. Remove all standard carburettor

control mechanism but retain pull wires

trunnions and adjusters, these will be reused.

The kit consists of 3 sets of components

comprising of one each of the following,

machined aluminium link, countersunk

top hat bush, threaded top hat bush

and M5 countersunk screw. The pull wires

may need the extra nipple removing as in

figure 2.

Figure 2 showing pull wire on left with nipple removed, other two assembled

ready to be installed into carbs.

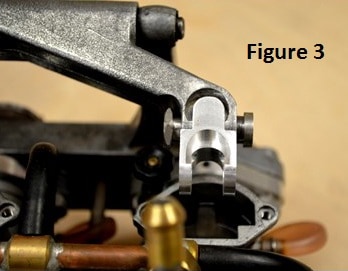

Step 7. Figure 3. Shows the method of

assembling the components, when

tightening the screw make sure the extension

piece is fully positioned in the

bottom of the gantry, owing to the hand

finished nature of the gantry it may be

necessary to fettle the external radius

to enable the proper fitting of the top

hat bushes to allow the screw to align.

If the centre one is assembled first it is

easier to gain access the screw.

Figure 4-5

Tighten the countersunk screw fully (Figure 4) ,

when doing this it is suggested that you align

one flat of the hexagon vertically to assist

clearance of the radius on the inner corner

of the casting. You might like to apply some

thread lock to the screw for added security.

The pull wires, adjusters and trunnions are

assembled as they were in the original set-up, see picture (Fig.5)

Step 8. Drop the slide assembly into the carburettor body making sure the

throttle needle enters the needle jet hole in the bottom of the carburettor bore.

Secure the top with the Phillip’s screws to the carburettor body. Bolt your new

JRC carburettors to the gantry using the O rings provided. Tighten the 6 securing

nuts to just past snug, do not over tighten.

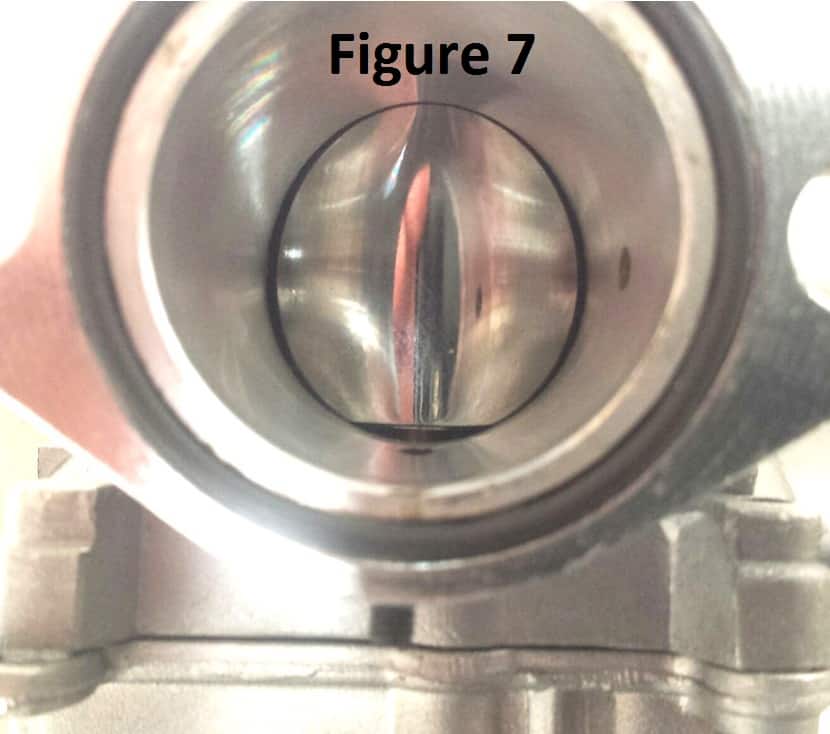

Slide the trunnions into the gantry

(Figure 6) arm with the slot outward. Insert the lifting rods through the new

gantry extensions and loosely tread the lifting rod down until the throttle slide

is completely closed and no light can be seen through the inlet of the carburettors.

Now turn the idle screw on the gantry until a slight gap can be seen at the

base of the throttle slide and the carburettor bore (Figure 7 ). Adjust the throttle

rods on all 3 carburettors so that the gap is identical for all 3 and lock down the

larger throttle rod lock nuts.

Step 9. Using care slide the gantry back into the inlet manifold rubbers. It is

recommended that you replace these rubber manifolds if they have become

hard or are cracked. The Triumph part number is 70-9060 and are available

from us or a reputable dealer. Do not use radiator hose as it is not suitable for

use with gasoline. Connect the throttle cable to the gantry.

Step 10. Fabricate fuel lines using the fuel hose and clamps supplied along

with the Tee fittings supplied. Always use clamps with fuel hose. We have left

the fuel line Simi finished so you can adjust it to your fuel tank style.

Step 11. Remove the rubber grommets and steel rings in the

air box. Install the large O rings supplied with the kit on the

mouth of each JRC carburettor and install the air filter assembly

leaving out the thick grommets and sleeves. By removing

the large grommets originally on the filter the air filter can

move forward enough to compensate for the slightly longer

JRC carburettor.

Step 12. Reinstall fuel tank. Attach fuel lines and turn fuel on

checking for any leaks. Reattach battery leads.

To cold start pull up on the large black knob on each carburettor

(Figure 8) .

These enrich the mixture for cold

starting. Start the engine and allow to come up to operating

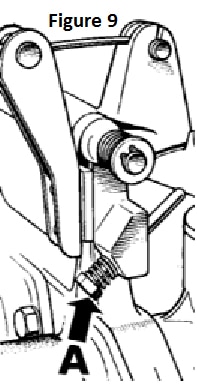

temperature. Adjust the idle speed using the large adjuster

on the original gantry (A).

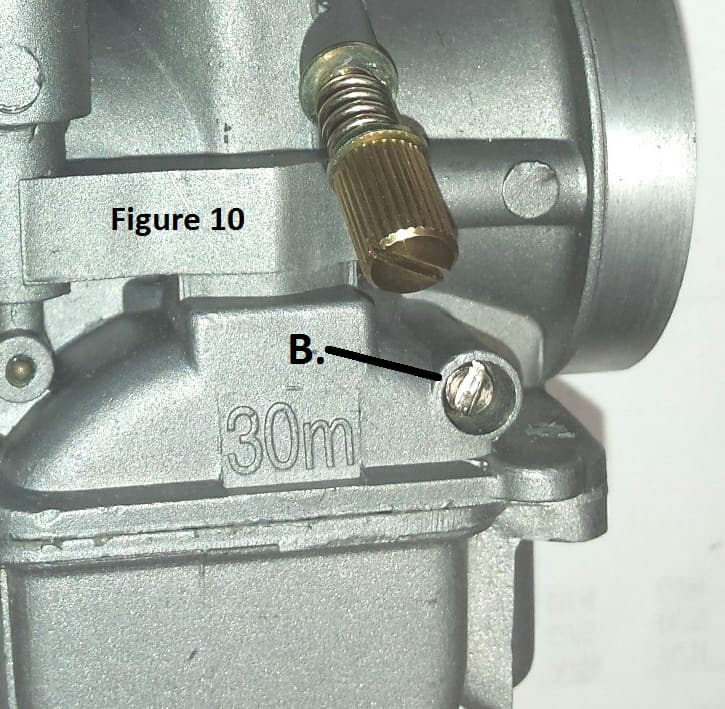

Turn the air screws ( Figure

10- B )on the side of each

carburettor slightly in or

out until the idle speed

picks up a bit. Do this for

each carburettor and then

set the idle speed to 6-700

RPM using the larger gantry

adjuster (A ) figure 9.

It is advisable to turn fuel off whenever the engine

is not in use.