Vape Ignition Installation and Troubleshooting

Click here to download the installation instruction PDF

Table of Contents

Vape Electronic Ignition For British Motorcycles

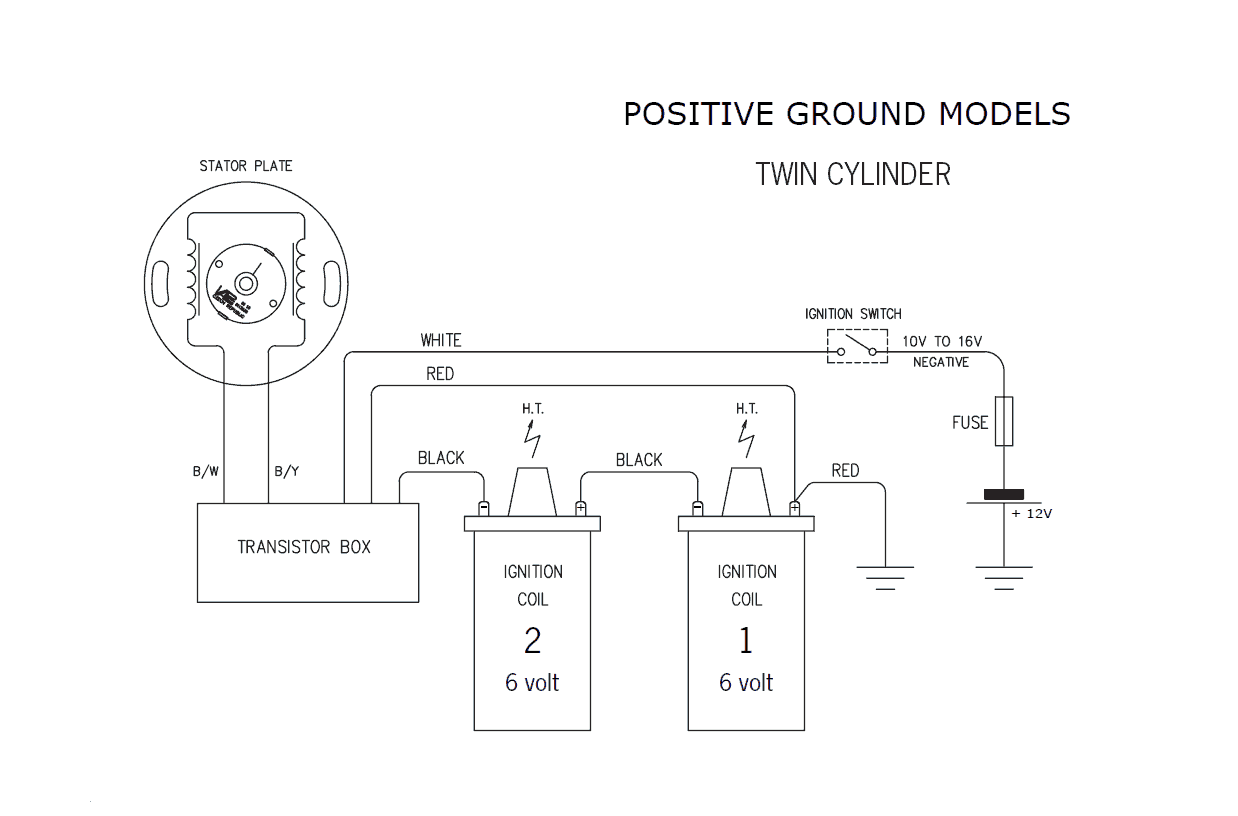

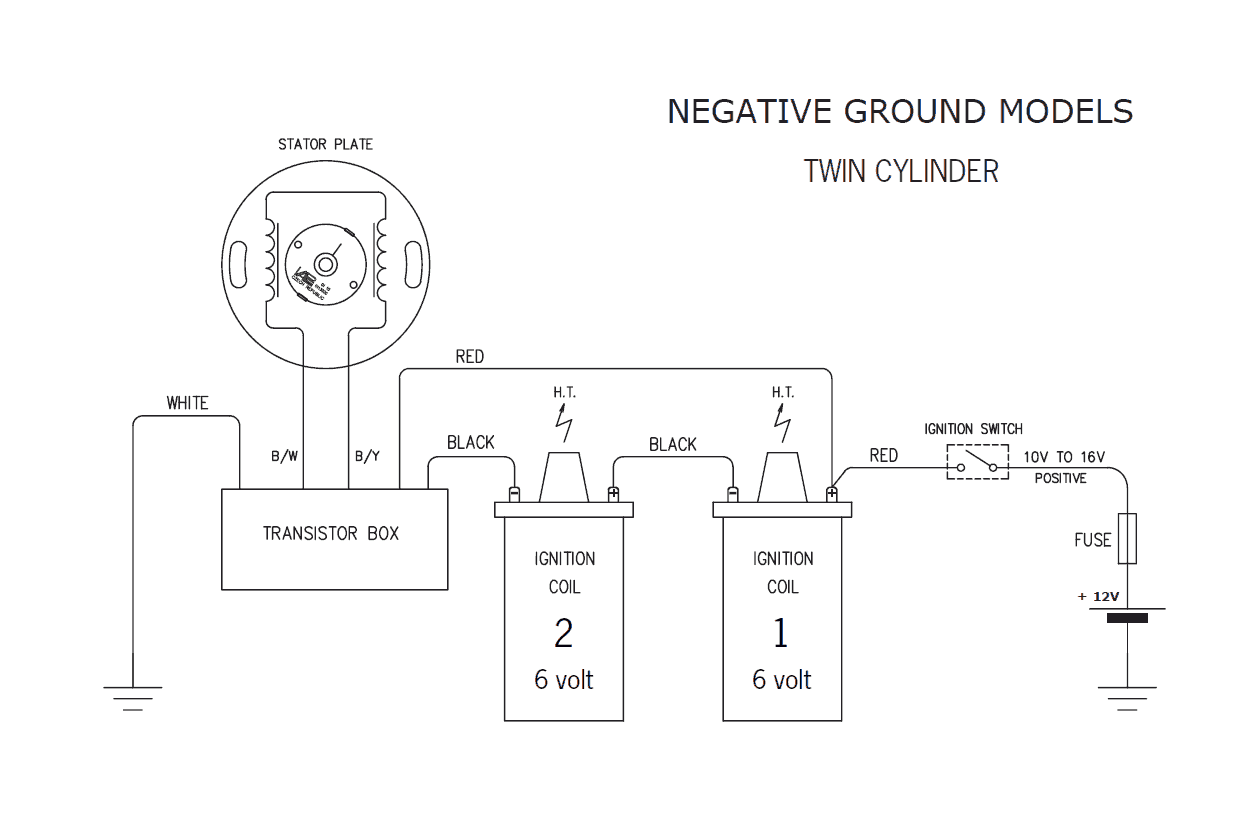

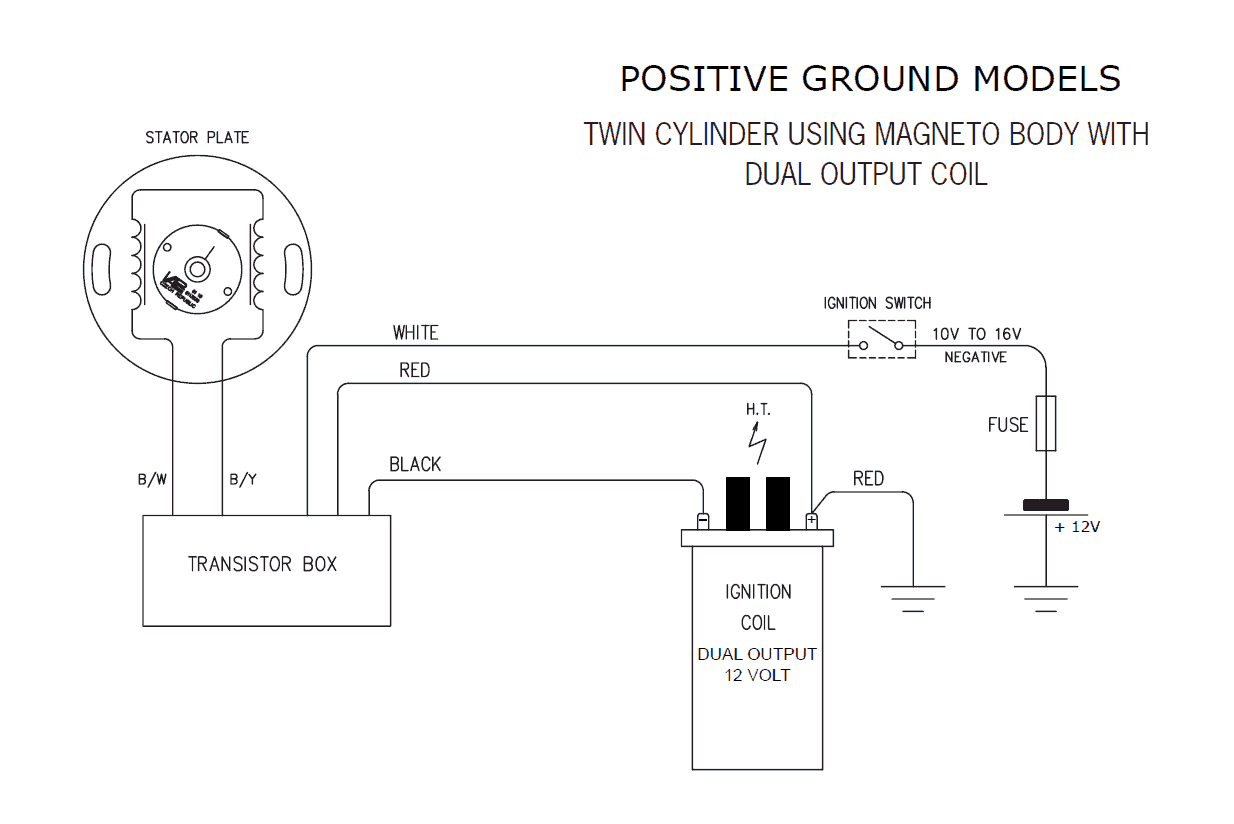

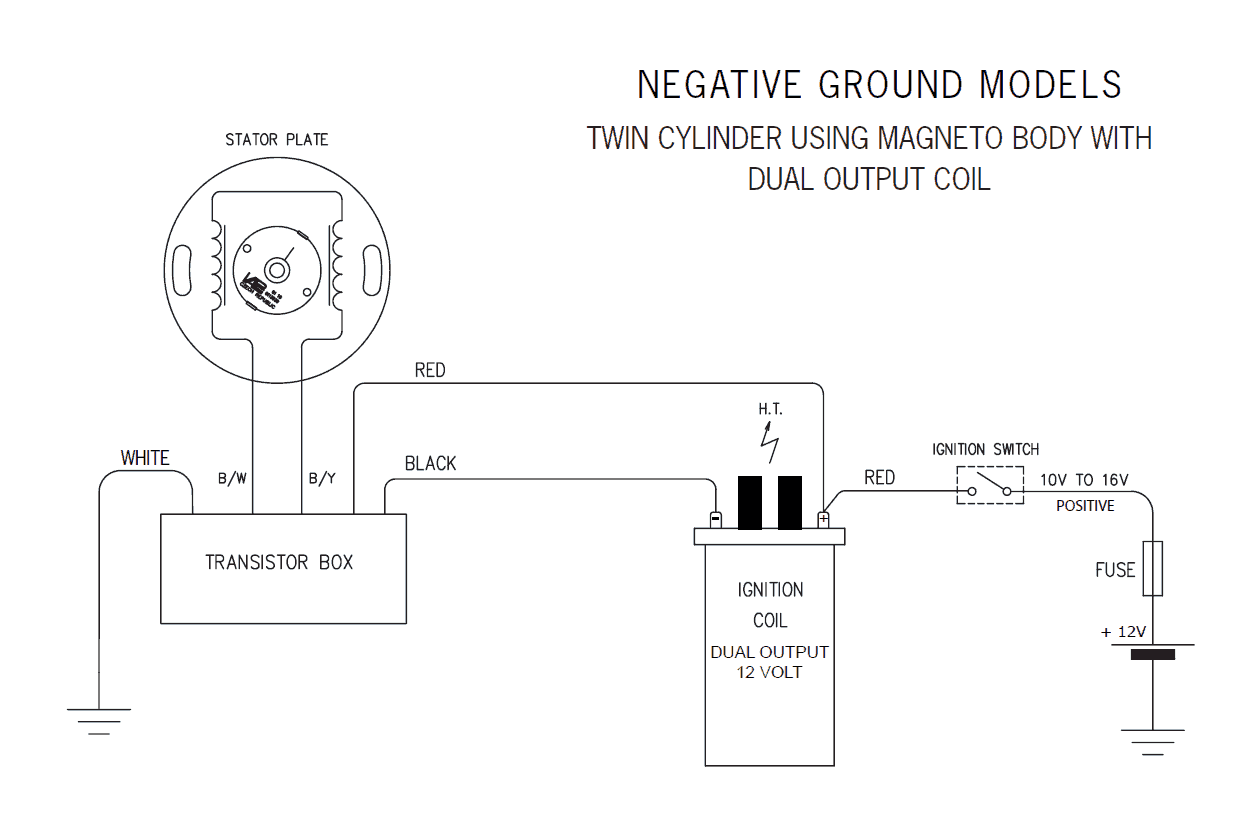

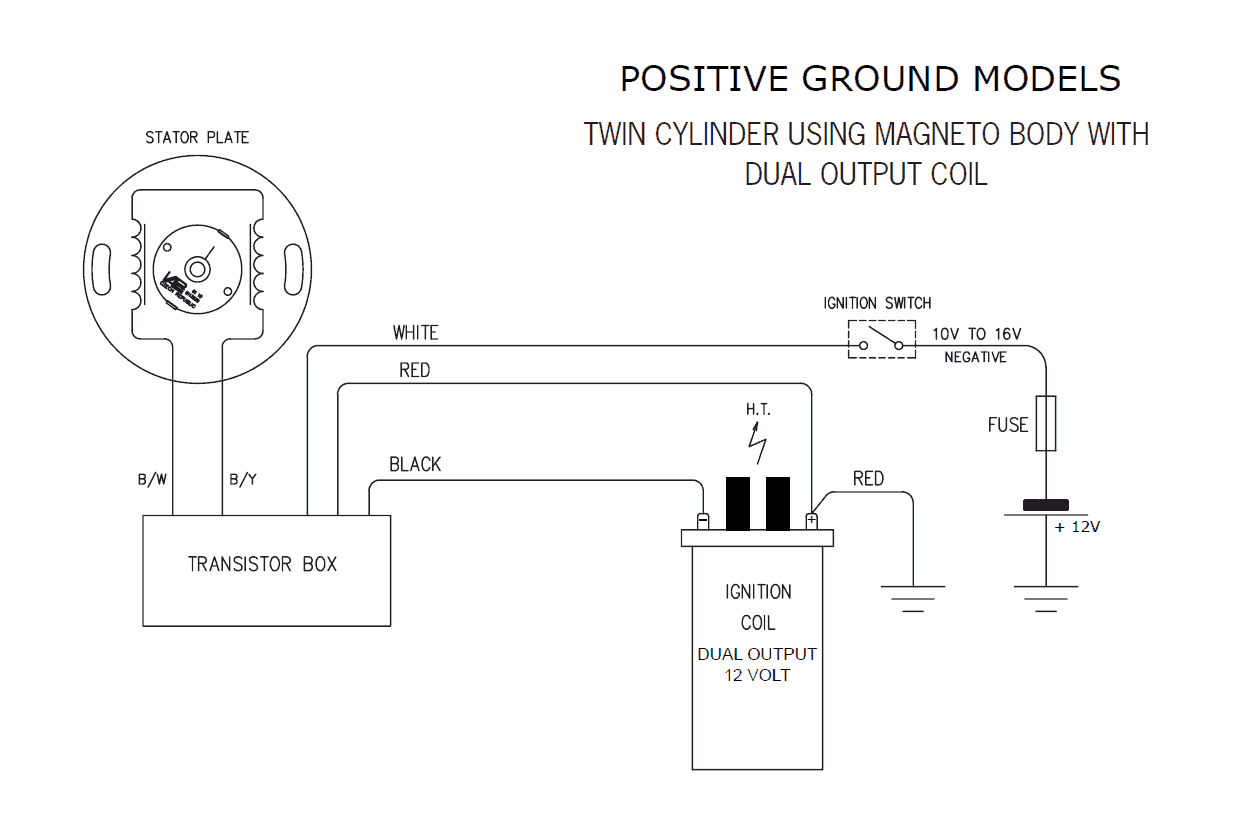

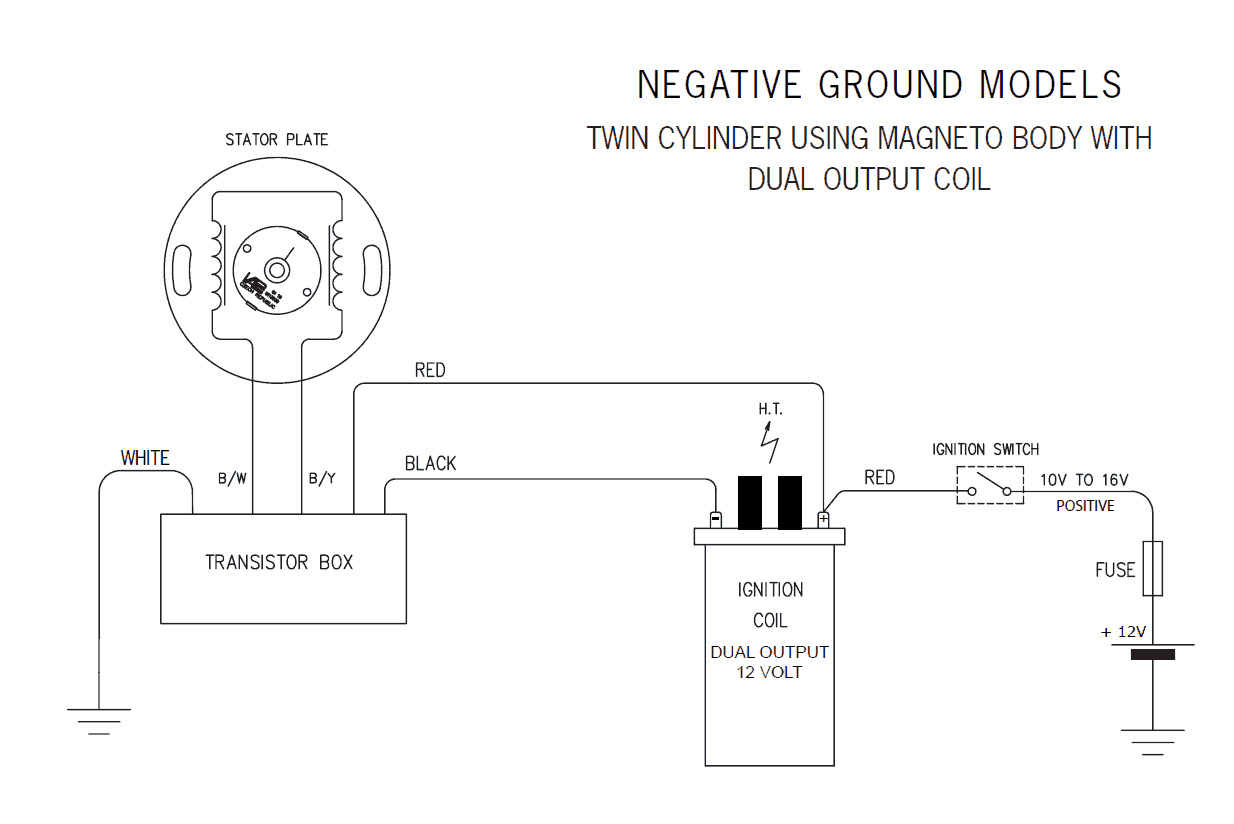

12 VOLT IGNITION – TWIN CYLINDER MODELS

POSITIVE OR NEGATIVE GROUND WITH POINTS IN THE SIDE CASING

GENERAL DATA

This unit can work with positive or negative earth as long as the coils are fed from a positive

supply. The working voltage is 10-16 volts. The maximum current through the unit must not

exceed 5 amps. For road applications two 12 volt coils in series are satisfactory and for race

applications a double ended coil with primary resistance of 3-4.5 ohms will give best results. Any

short circuit on the ignition coils will damage the unit. The coil current should drop to zero after

2 seconds without triggering. The resistance of the stator coils should be 73 ohms each and the

magnetic rotor should have south poles facing outwards.

This unit can be adapted for use on engines firing at 180 degrees camshaft or 360 crankshaft

degrees. This unit will operate two coils to 10,000 sparks per minute. The typical working

advance is 10 degrees at 2500 RPM. This unit must be operated with the frame chassis acting

as an electrical return, whether positive or negative polarity. If the engine is rubber mounted a

good engine earth strap must be fitted. This unit will operate from an alternator, rectifier, zener

diode and capacitor battery-less system but starting may be more difficult. If the zener diode

disconnects when the engine is running the unit may be damaged. Both spark plugs are fired

at the same time thus, if the engine only runs on one cylinder, the fault can be traced to a

mechanical/spark plug/ignition coil/ht lead and not the transistor pack or stator plate.

IGNITION TIMING FOR BRITISH TWINS

TRIUMPH TWIN CLOCKWISE 38 degrees fully advanced

BSA TWIN ANTI CLOCKWISE 34 degrees fully advanced

NORTON COMMANDO ANTI CLOCKWISE 28/31 degrees fully advanced

NORTON ATLAS CLOCKWISE 28/31 degrees fully advanced

RECOMMENDED IGNITION COILS

6 VOLT SINGLE OUTPUT COIL

12 VOLT DUAL OUTPUT COIL

HT LEADS & SPARK PLUG CAPS

We recommend fitting a good quality 5k resistor type plug cap

Non-resistor caps can also be fitted

INSTALLATION INSTRUCTIONS – TWIN CYLINDER

Warning: This unit can produce high voltages.

Always disconnect the battery before working on the system!

1 Disconnect the battery

2 Remove the petrol tank and/or seat for access to the ignition coils & condensers

3 Remove the contact breaker plate and automatic advance unit

4 Trace the two contact breaker wires (normally black, white/black or yellow) up to the

condenser pack/ignition coils and disconnect. These are no longer required

5 Remove the other wires from the ignition coil terminal`s. These will be negative feed wires

from the ignition switch

6 Link the coils using the black link wire. The negative of one coil to the positive of the other. Cut

the link wire to the correct length and ensure female lucar connectors are crimped/soldered

7 Using the red positive earth wire, connect the positive of the first coil to a good frame earth

or positive battery terminal on positive earth models (via the ignition switch feed on negative

earth models). See the appropriate wiring diagram for your model

8 Find a position for the transistor box near the ignition coils and mount using cable ties.

Ensure both wiring block connectors can be accessed to attach the wiring

9 Connect the black wire from the transistor box to the negative on the second coil (see wiring

diagram).Remove the outer protective sleeve and cut the wire to required length.

Re-fit sleeve as required

10 Connect the red wire from the transistor box to the positive terminal of the first coil (same

point as the earth wire. See wiring diagram)

11 Connect the white wire from the transistor box to the ignition switch feed on POSITIVE

ground models and to a suitable earth on NEGATIVE ground models (see wiring diagrams).

Remove outer protective sleeve and cut wire to the required length. Re-fit sleeve as required

12 Connect the black/yellow from the transistor box to the black/yellow from the stator plate.

Both black/yellow and black/white share a common sleeve. Cut the sleeve to desired length

13 Connect the black/white from the transistor box to the black/white from the stator plate

14 Insulate the ends of any unused wires and check all connections are good and tight fitting

15 Remove the timing inspection cover from the alternator side of the engine

16 Set the engine at the fully advanced timing mark on the compression stroke

17 Fit the magnetic rotor in to the end of the camshaft in the contact housing using one of the

bolts supplied (either BSF or UNF depending on model). Check that the bolt does not bottom

on the thread. If it is too long, cut off a small amount of the thread

18 Hold the stator plate in the contact breaker housing. Centralise the adjustment slots and turn

the magnetic rotor on its taper until the timing mark lines up with the appropriate timing mark.

Anti-clock A or clock C, depending on model. This must be done without moving the engine

setting.A rotor spanner is provided to move the rotor (good tip: mark the stator timing position

on to the engine case with a marker pen and align the rotor timing mark to it).

The stator plate should be central on the adjustment slots, with the rotor timing mark central

in the timing position hole

19 Tighten the rotor locating bolt and check the engine position has not moved

20 Fit the stator plate with pillar bolts and connect the black/white & black/yellow wires to the

stator plate using male bullet connectors

WIRING: All connections must be of the highest quality crimped and/or soldered. Twisted

wires will not give satisfactory operation. Also, avoid coiling up any surplus wiring. Cut

to length and make new connections where required

21 Refit the tank seat and re-connect the battery

22 Start the engine and warm it up to normal working temperature for 4-5 minutes. Connect a

strobe lamp and time with the engine running at 4000-5000 RPM. This is adjusted by sliding

the stator plate on its slotted holes. If timing marks cannot be aligned before the end of the

adjustment slots then the magnetic rotor must be re-positioned

23 Refit the contact breaker cover and alternator timing cover. The timing is now set and should

require no further adjustment

CLICK PICTURE TO ENLARGE

12 VOLT IGNITION – SINGLE CYLINDER MODELS

POSITIVE OR NEGATIVE GROUND WITH POINTS IN THE SIDE CASING

GENERAL DATA

This unit can work with positive or negative earth as long as the coil is fed from a positive

supply. The working voltage is 10-16 volts. The maximum current through the unit must not

exceed 5 amps. For road application a 12 volt coil is recommended. Any short circuit

on the ignition coil will damage the unit. The coil current should drop to zero after 2 seconds

without triggering. The resistance of the stator coils should be 73 ohms each and the magnetic

rotor should have south poles facing outwards.

This unit can be adapted for use on engines firing at 180 degrees camshaft or 360 crankshaft

degrees. This unit will operate two coils to 10,000 sparks per minute. Typical working advance

is 10 degrees at 2500 RPM. This unit must be operated with the frame chassis acting as an

electrical return, whether positive or negative polarity. If the engine is rubber mounted a good

engine earth strap must be fitted. This unit will operate from an alternator, rectifier, zener

diode and capacitor battery-less system but starting may be more difficult. If the zener diode

disconnects when the engine is running the unit may be damaged. Both spark plugs are fired

at the same time thus, if the engine only runs on one cylinder, the fault can be traced to a

mechanical/ spark plug/ignition coil/ht lead and not the transistor pack or stator plate

IGNITION TIMING FOR BRITISH SINGLES

BSA C15/B40 ANTI CLOCKWISE 33.5 BTDC full advance

BSA B25 ANTI CLOCKWISE 37 BTDC full advance

BSA B44 ANTI CLOCKWISE 28 BTDC full advance

BSA B50 ANTI CLOCKWISE 34 BTDC full advance

T20 CUB -67 ANTI CLOCKWISE 36 BTDC full advance

T20 CUB 67- ANTI CLOCKWISE 32 BTDC full advance

RECOMMENDED IGNITION COILS

12 VOLT SINGLE OUTPUT COIL

INSTALLATION INSTRUCTIONS – SINGLE CYLINDER

Warning: This unit can produce high voltages.

Always disconnect the battery before working on the system!

1 Disconnect the battery

2 Remove the petrol tank and/or seat for access to the ignition coils & condensers

3 Remove the alternator rotor cover if fitted

4 Loosen the automatic advance unit centre bolt

5 Rotate the engine to the correct full advance timing position (see additional timing

information).These rotor marks should be checked for correct alignment and should line up

with the engine set in the full advance position. If in doubt, check with a timing disc and dial

gauge in the spark plug hole, then re-mark the rotor as required. Models produced after 1969

have a timing plug on the left hand crankcase

6 Remove the kick start and gear lever and remove the outer timing cover

7 Remove the contact breaker plate and lead

8 Remove the automatic unit centre bolt and remove the auto advance unit. This can be done

by using the extractor bolt supplied, or a light tap sideways will remove it from the taper

9 Fit the magnetic rotor in place of the automatic unit using one of the bolts supplied, either BSF

on pre 1968 engines or UNF on later models. Check the bolt does not bottom on the thread.

Shorten the bolt if required. Do not tighten the bolt as adjustment will be required

10 Hold the stator plate in the contact breaker housing. Centralise the adjustment slots and turn

the magnetic rotor on its taper to align it with the appropriate timing mark (anti-clock A clock

C depending on model). This must be done without moving the engine static setting (mark

the stator timing mark position on to the engine case with a marker pen and align the rotor to

it). The stator plate should be central on the adjuster slots with the rotor timing mark central

in the timing position hole

11 Check the engine has not moved and tighten the rotor fixing bolt

12 Fit the stator plate with pillar bolts and connect the black/yellow & black/white wires to the

stator plate. Bullet connection ensure wires are connected the right way round as this will

affect ignition timing. Route the wires through the appropriate grommet clips on the inner

timing cover and secure them to the front frame tube with cable ties

13 Refit the outer timing cover and kick start/gear levers

14 Remove all wires from the ignition coil terminals. These will be the original CB lead and feed

from the ignition switch and the external condenser if fitted

15 Find a position for the transistor box near the ignition coil and mount using cable ties. Ensure

both wiring block connectors can be accessed to attach the wiring

INSTALLATION INSTRUCTIONS (cont)

NEGATIVE GROUND ELECTRICS

16 For NEGATIVE ground electrics take the black lead from the transistor box. Cut to length

and connect to the negative coil terminal using an insulated spade terminal

17 Take the red wire from the transistor box, cut to length and connect to the positive ignition

coil terminal with an insulated spade terminal

18 Connect the ignition switch feed wire to the positive terminal of the ignition coil

19 Take the white wire from the transistor box, cut to length and connect to a good grounding

point (negative [-] battery terminal recommended)

POSITIVE GROUND ELECTRICS

20 For POSITIVE ground electrics take the white wire from the transistor box, cut to length and

connect to the ignition switch feed wire previously connected to the ignition coil

21 Take the red wire from the transistor box and connect to the ignition coil positive terminal

22 Take a separate ground wire from the positive coil terminal to a good grounding point

(positive [+] battery terminal recommended)

23 Take the black wire from the transistor box, cut to length and connect to the negative ignition

coil terminal

WIRING: All connections must be of the highest quality crimped and/or soldered. Twisted

wires will not give satisfactory operation. Also, avoid coiling up any surplus wiring. Cut

to length and make new connections where required

24 Refit the tank seat and re-connect battery

25 Start the engine and warm it up to normal working temperature for 4-5 minutes. Connect a

strobe lamp and time with the engine running at 4000-5000 RPM. This is adjusted by sliding

the stator plate on its slotted holes. If the timing marks cannot be aligned before the end of

the adjustment slots, then the magnetic rotor must be re-positioned

26 Re-fi t the contact breaker cover and alternator timing cover. The timing is now set and should

require no further adjustment

27 EARLY C15 / B40 / T20 MODELS DO NOT HAVE PROVISION FOR STROBE TIMING

so road testing will be required for optimum performance. Adjust the stator plate as later

models. NOTE: As the camshaft rotates at half the engine speed, 20 degrees crank

movement is equal to 10 degree camshaft movement

TROUBLESHOOTING

NO SPARK

1 Check the battery has power

2 Using a test bulb or voltmeter/multimeter check for a power feed to the ignition module from

the ignition switch. Measure between the ignition feed wire and ground with ignition switch on

3 The voltage reading here should be the same as the voltage on the motorcycle battery

(12volts). If a significantly lower voltage is detected then this can indicate a faulty ignition

switch or a bad connection in the ignition circuit/wiring loom. A simple test is to take a direct

feed from the battery to the ignition pack, bypassing the normal feed from the ignition switch

STATOR PLATE

1 Check wiring connections on black/white / black /yellow wires. Check for any visible signs of

damage on the stator plate and ensure the rotor is correctly located in taper seating

2 Using a multi meter check continuity through the stator plate. Set the meter to ohms. The

resistance reading for each coil should be 73 ohms. Connect the meter to the black/white &

black/yellow leads and the combined resistance should be 146 ohms

SPARKS ON CRANKING BUT ENGINE WILL NOT RUN

1 Check polarity of wires from the ignition module to stator (y/b to y/b & w/b to w/b). If these

wires are connected incorrectly ignition will produce a spark but the timing will be retarded

CONTINUOUS SPARKING WITHOUT CRANKING ENGINE

1 This indicates a poor supply to the ignition. Check battery for a bad cell. A bad battery with

charger connected can cause this problem

2 Check for good engine earth connection and battery earth point

3 Wrong type of ignition coil fitted with low primary resistance

2 thoughts on “Vape Ignition Installation and Troubleshooting”

jose garcia

October 13, 2020 at 2:32 pm

have installed a wassel electronic ignition and it fails at high rpm … what can it be?

the ignition time is correct, it starts well. Wires well connected, coil with correct resistance Spark plug pipe with 5k resistance

Nick Willcutt

October 14, 2020 at 9:47 am

Hello Jose,

The Vape ignition, like the others we stock, have a built in rev limiter. The sparks will stop at about 9500 rpm. If the loss of spark is occuring below this you might want to send it to us for testing.

Regards,

Nick

JRC

Comments are closed.